Units are in stock and ready to ship, Contact us for more information!

The MoRT RP75 is designed to remove the roll sets from Ocrim roller mill stands. It can carry a roll pack weighing up to 3200 lbs. The hydralic platform allows it to be used for single high and double high stands.

Battery powered drive system allows you to drive the PR75 to and from your roll stand. The Mechannum omnidirectional wheels provide unlimited directional control so you can maneuver into the tightest of spaces.

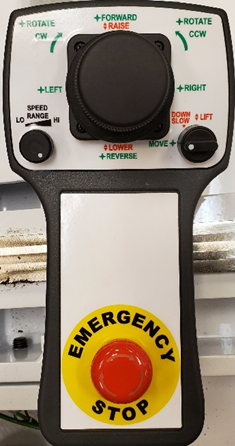

Controlling the MoRT RP75 is intuitive and easy. A simple, 3 axis joystick on the pendant provides input for both direction and speed. Push it forward and the MoRT RP75 moves in that direction. Push the joystick sideways and it moves sideways. Rotate the joystick knob and the MoRT RP75 will spin around its center. Any combination of moves is also possible because of the Mecannum wheel design.

Moving the 3 position switch to the lift position repurposes the joystick functions to lift/lower functions. Pushing the joystick up extends the lift cylinders and pulling the joystick back will collapse the cylinders. The Down-Slow (middle) position allows for a slower lowering of the carriage.

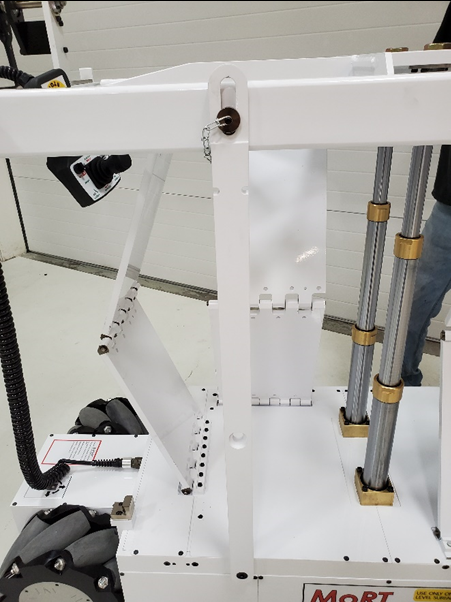

Safety chains prevent the MoRT RP75 from tipping when it is in an elevated position. They are are deployed by attaching the clamp to the center rib on the roll stand and the loose end of the chain is fed through the key hole catch on the side of the carriage.

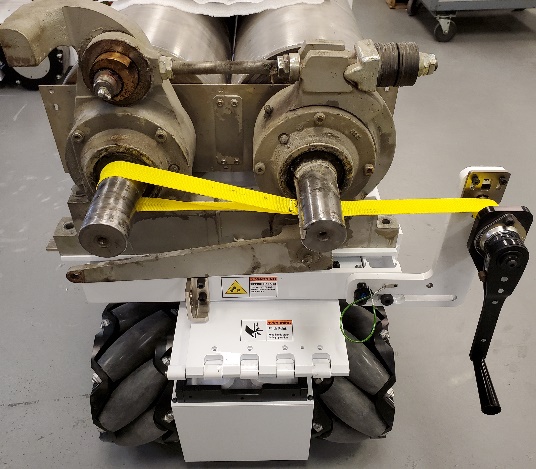

The roll pack may now be rolled from the stand onto the RP75. This is accomplished by unwinding the green straps and slipping the loop around the roll shaft as shown. Both ratcheting winch handles are employed to winch the roll pack onto the carriage. Once the roll pack is free of the stand on fully on the carriage, the winch lock can be lowered, locking the strap winch. Insert safety pin through at least one of the roll pack mounting holes into the carriage as a safety precaution

Safety bars may be deployed when the carriage is raised to near full height or at work height. They are stowed on each side of the body. The slotted hole is designed to be used when removing or installing a roll pack. The slot allows for some height variation while still providing safety. The middle slot is designed to be used when working on the roll while it is only slightly elevated. Using this position will prevent unnecessary stress being applied to the Sarus (stiffener) plates when removing or installing pulleys and other mechanisms.