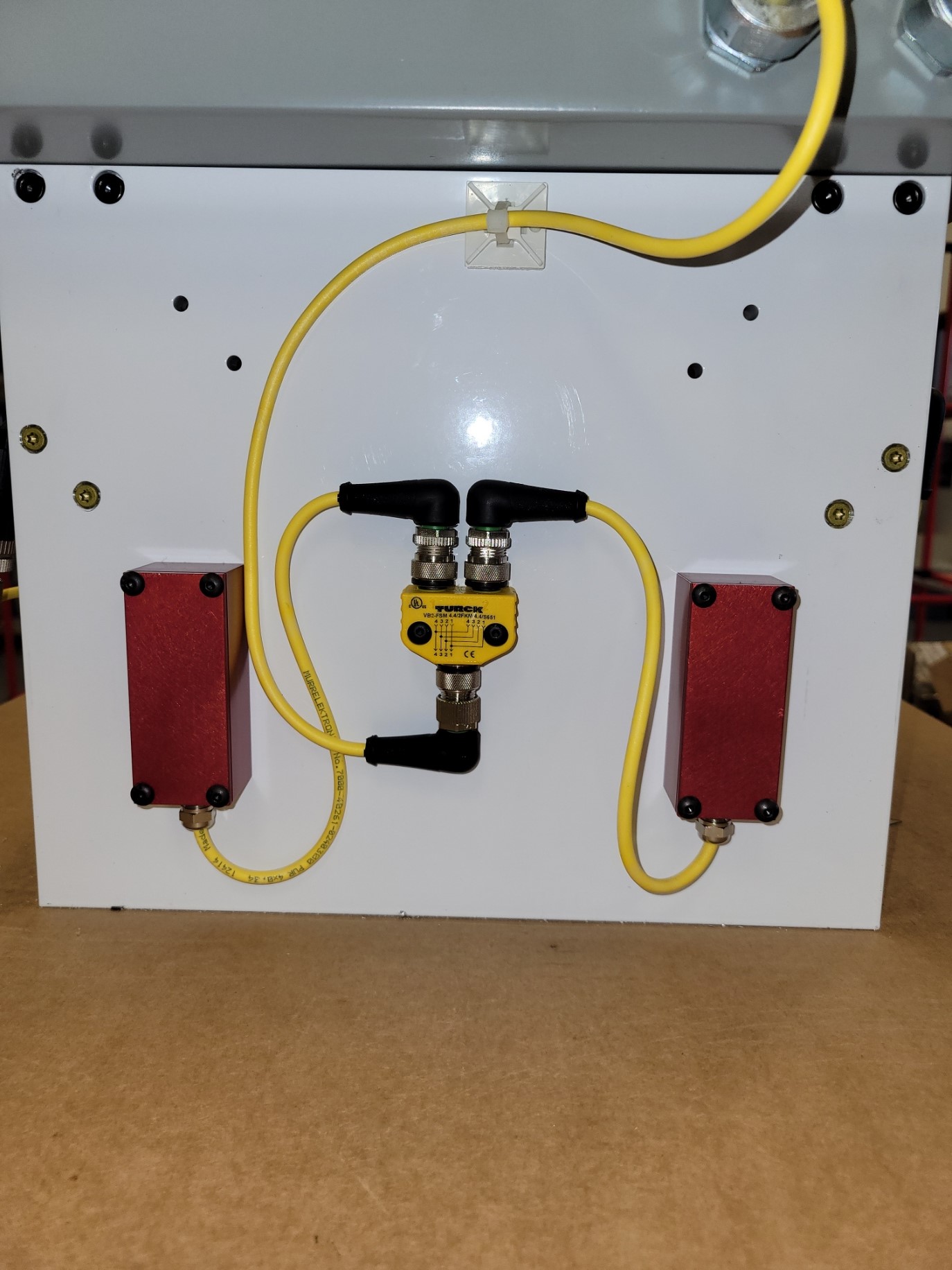

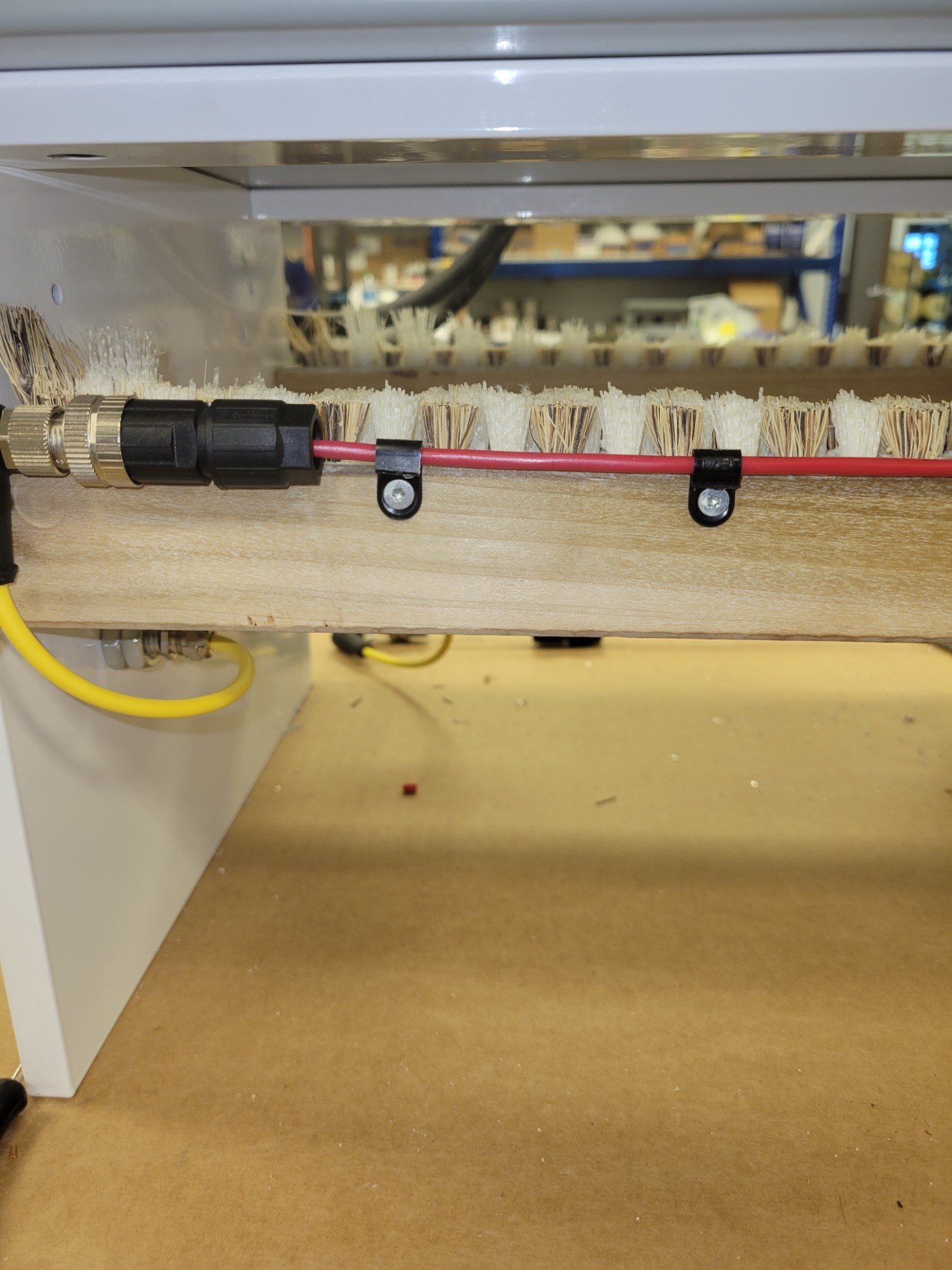

The Roll Stand Temperature Detection system will provide a visual and audible alarm in the event the temperature inside a roll stand exceeds a designated temperature giving an operator time to inspect and correct the problem before ignition can occur. The system can be specified for 155°, 172°, 190°, 220°, 365° or 455°. A sensor wire is mounted inside the stand under each pair of rolls and normally fixed to the roll brush. It is connected to a small junction box which contains end of line (EOL) resistors and mounted in an inconspicuous area. The EOL resistors allow the system to detect open/short failures in the communication wiring. The communication wire exits the junction box and is conjoined with the opposite side sensor where both communication signals are passed along to the control panel.

The communication wiring, EOL resistors and sensor wire is C2D1 compliant because we use intrinsically safe barriers inside the control cabinet which limit the energy entering the hazardous environment. The control cabinet will need to be installed in a non-hazardous environment.

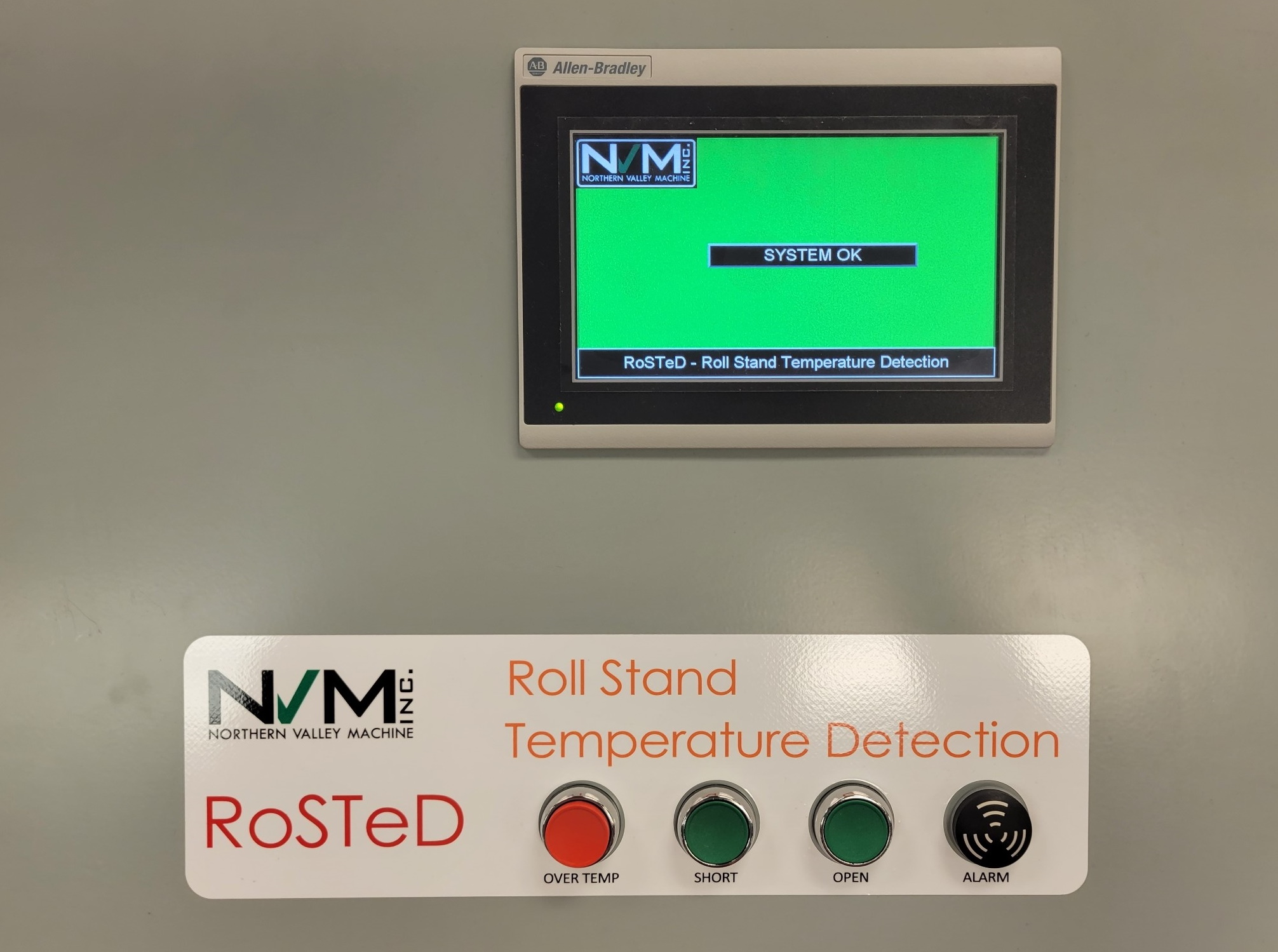

The interface between the mill operator and the detection system is an HMI touchscreen. The screen may either be mounted in the control cabinet or mounted remotely up to 100 meters away from the controls. The visual cues are quite simple by design. The background is green and a “System OK" banner is displayed.

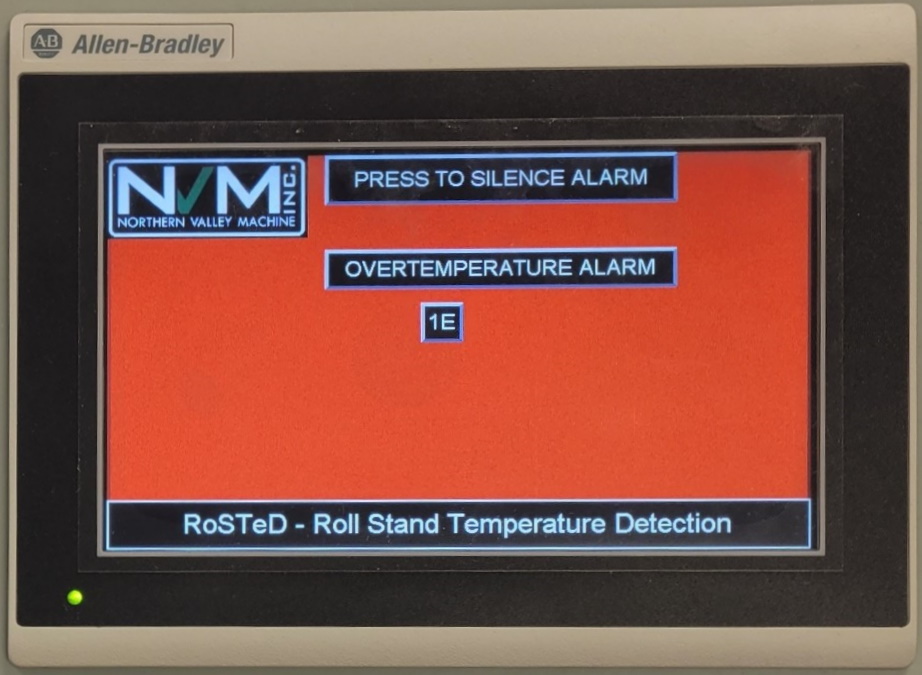

In the event of an overtemp condition, the background becomes red and the banner indicates the location of the alarm. In addition, a buzzer emits a continuous audible alarm which may be momentarily shut off. Either a short or open circuit in the control wiring will cause the same change to the screen but the audible alarm is changed from steady to intermittent chirping.